3D medical models

Boost your business with our expertise in developing software for 3D medical model creation. That kind of software enables the conversion of medical images into highly detailed, interactive 3D representations of anatomical structures and also 3D models ready for printing.

These models have various applications such as surgical planning, preoperative simulations, diagnostic analysis, educational aims, and also the design of custom medical implants or prosthetics.

3D modelling of medical images significantly enhances precise treatment and supports personalized medicine development.

Software development for 3D medical models development

Accelerating surgery both planning and simulation

Reinforcement of medical education and also surgery training

Improvement of implant design

Conducting medical imaging research

Creating precise, patient specific 3D-printed medical model

Precise image of the patient anatomy

3D modelling software development: selected works

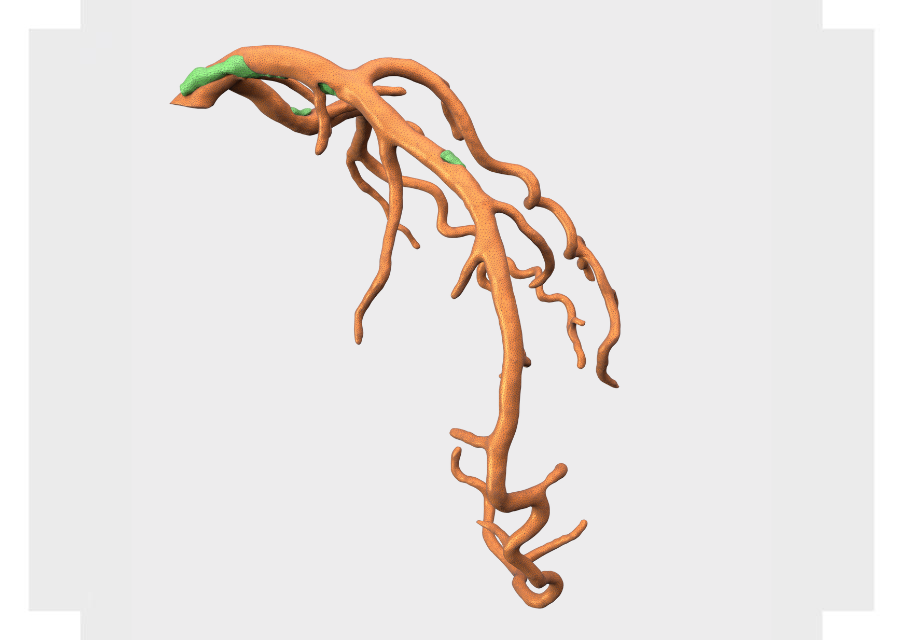

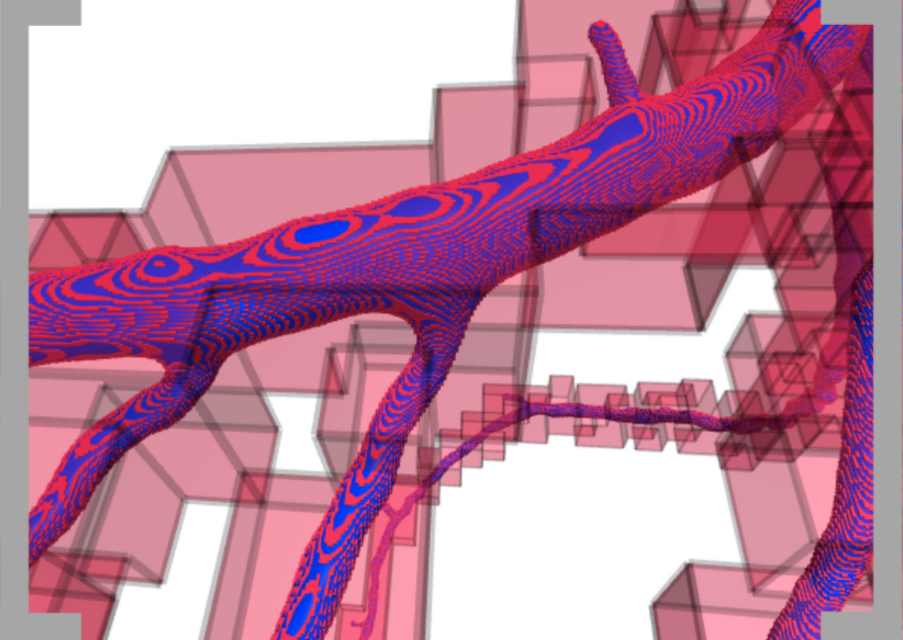

HIGH-PRECISION MESH GENERATION

Coronary vessels are tiny structures, without a doubt the segmentation of which requires special techniques. One aspect relates to the accurate reconstruction of complex geometry. We use advanced models to generate and process meshes and also convert from a sparse, high-resolution representation of voxels using VesselEngineTM. Our data is ready for both physical modelling and visualization tools.

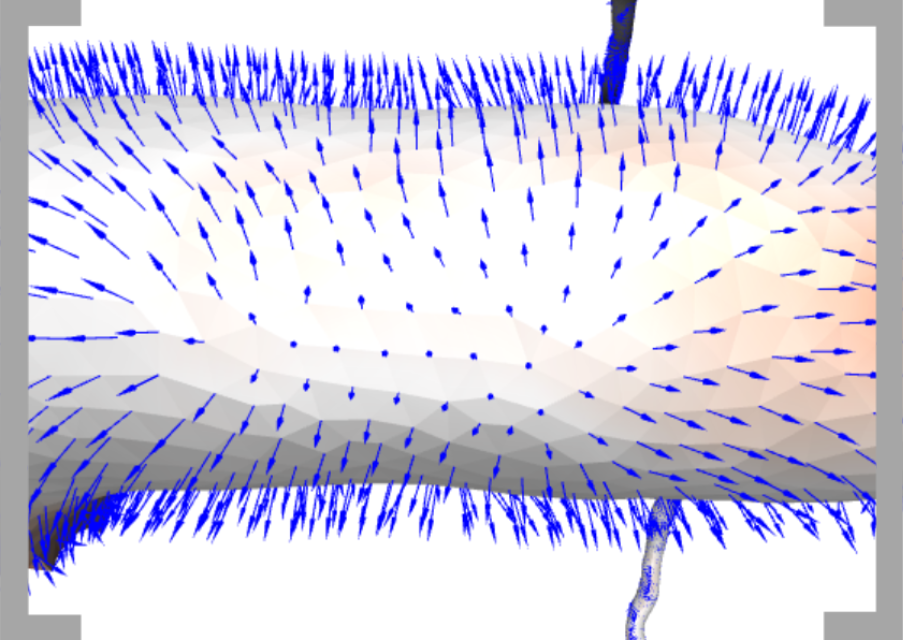

3D MESH MODELLING AND ANALYSIS

Mesh reconstruction is based on an interaction between an anatomic prior: vessel walls should be straight and noisy image data. Below we show an example of an analytic tool that allows explicit verification of mesh deviation from ideal segmentation. The vector field shows the place where the mesh deviates from the maximum gradient module.

3D printing and additive manufacturing

Thanks to 3D printing and additive manufacturing medical companies can create exact patient specific 3D medical models. The key aspect is that the preparation of a 3D model must be fully automatic – on the other hand, the basic requirement is to ensure the maximum precision of such a printout to reflect the patient anatomy as accurately as possible.

We have experience working on precise STL (stereolithography, standard triangle language creation) for 3D printing.

Our experience in 3D modelling creation solutions

Algorithms developed by us automatically generate a 3D model and prepare the model for printing, while maintaining maximum print precision (the possibility to accurately create a 3D model matched to the patient anatomy).

Ground-truth preparation – we have experience in creating high quality segmentation based on diverse, large sets of image data. Segmentation is used as input for training neural networks in 3D medical image processing.

We are able to build algorithms from scratch that tackle the majority of issues that arise in the practice of accurately preparing geometry for 3D printing and maintaining simultaneously high tolerance for medically important parameters.

Our experts create physical 3D modelling software and as well as 3D printable models matched to the patient needs and anatomy requirements. Moreover, we specialize in converting MRI and CT into high accurate medical imaging models.